Our Commitment To Quality

Our Commitment To Quality

Materials

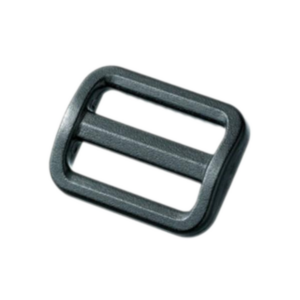

Quality in manufacturing begins with materials. We put a lot of effort into finding and using the right materials for the job. We have a huge range of webbings and other materials to choose from to ensure that we get the appropriate item. The majority of our harness webbing is made in Australia with a few specialised products bought in directly from America. Buckles for harnesses are made in Italy and the UK, and our rings and connections either made in Italy or America.

Construction

Rather than fix on a single construction technique and follow it slavishly for every product as many manufacturers do, we use the most appropriate method of construction to suit the style of the product. This results in a highly diverse range with no two products alike. We don’t just strive to meet a standard we like to exceed it. Once they have passed a standard test we often fine tune and retest until we are happy the strength we have is as good as it is going to get.

Inspection

All our harnesses go through a careful two-stage inspection process to ensure that the product is 100% and the finish is perfect. Faults such as loose stitching and webbing flaws are excluded by our quality control system from reaching customers.

Standards

Since 1994 we have represented New Zealand on the committee which formulated the height safety harness standard for Australia and New Zealand. Our work at height harnesses met this standard, and our climbing harnesses and outdoor education harnesses are designed to exceed the requirements of the European climbing harness standard, EN 12277. In early 2018 Aspiring Safety was certified to the internationally recongised standard for manufacturing quality of ISO9001, with internal reviews and checks regularly carried out and external audits conducted by the Australian based ECAAS PTY.

Our quality system and policy is now second to none. You can request a copy of our quality policy or ask any question you have in regards to quality by emailing our quality control manager – quality@aspiring.co.nz.

Product Testing

All our life-safety products go through destructive strength testing. Harnesses require extensive design testing prior to their release to the market, and later undergo periodic testing to ensure that no problems have crept into the manufacturing process. Any changes in design, materials, or procedures are tested before being introduced into production.

Much of our product and component testing is outsourced to the SAI Global product testing laboratory in Christchurch. SAI Global uses a Shimadzu test machine capable of 100 tons load, which is ideal for pulling webbing products such as slings to pieces. We also use other test labs when needed in Christchurch and Sydney for other specialised harnesses and proof testing of designs.

Our testing programme started back in the early 80s with the DSIR Materials Testing Laboratory in Christchurch, using a DSIR concrete dummy. In those days most testing was done by drop tests from a height of about 1.5 metres. This was spectacular to watch, but gave only a pass/fail result, and so was not very useful as the load applied could not be controlled.

Later DSIR was transformed into Industrial Research Ltd (IRL), and we used a large steel test bed, on which the dummy was laid and harness tests were carried out horizontally. With the closure of the IRL Materials Testing Lab in 1994, we developed our own test facility for static and dynamic testing of harnesses and other products.