Activities, Blog, Climbing

Why Fixe Ropes?

Fixe by ROCA

Roca is one of the oldest rope manufacturers in the world. In operation since 1891, in 2012 it went on to form part of Fixe, for which it currently makes all the ropes in its catalogue. Fixe ropes are backed up by more than 125 years of experience in the sector. All production is done in Sant Quirze de Besora (Barcelona).

Fixe was founded in 1983 in a place surrounded by mountains and premier climbing zones like Montserrat, Terradets and Siurana. It quickly became a leading brand among the climbing community, and its products are currently known worldwide.

With an image updated to the 21st century and a renewed catalogue, Fixe Climbing today produces its entire range of ropes and Alien Cams at its headquarters in Sant Quirze de Besora, it is the official European distributor of the Perfect Descent auto belay, and is also the distributor for Climbskin in Germany, Austria and Italy.

In manufacturing the ropes, Fixe uses Classic Plus 48 or Endurance braiding, both with 48 strands, unlike other brands that use 42-strand braiding.

Fixe also use an environmentally friendly Nature Treatment which does not contain chemical treatments. This makes it ideal for use in drier environments.

Ropes that use Endurance technology slide more easily over their working surfaces: carabiners, descenders, belays, anchors, etc. To achieve this, higher quality strands are used which, combined with the manufacturing system, enables Roca to produce ropes with unique characteristics on the market.

Endurance gives ropes a nicer feel, greater fluidity, and the ability to withstand 30% more abrasion cycles.

Fixe ropes that use Endurance braiding (known colloquially as herringbone braiding) are the following: Summit, Zen, Monkey, Dominator, IO Plus, Siurana, Rainbow, Pro Endurance, Canyon Endurance and Espeleo Endurance.

SPD Spiderwire technology optimises the performance of the fibres, achieving optimal balance in the rope as a whole. This increases the capacity of number of falls by 30% and achieves a lower impact force.

Thanks to SPD Spiderwire technology, small-diameter ropes have the same characteristics as large-diameter ones, without sacrificing a low impact force. These are lightweight and very strong ropes that are comfortable to handle.

Fixe has a range of ropes that use Full Dry technology in its catalogue. Maximum protection against ice, moisture and dust, increasing the sliding capacity and abrasion resistance.

All Fixe ropes that display the Full Dry seal comply with the UIAA Water Repellent requirements.

All ropes treated with FULL DRY absorb less than 5% of the rope’s weight in water. Recommended for practising mountaineering, ice climbing and for wet and dusty areas.

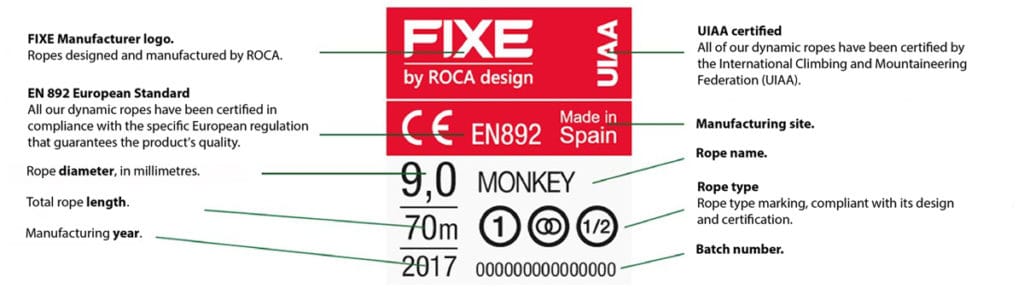

What Information should the Rope Include?

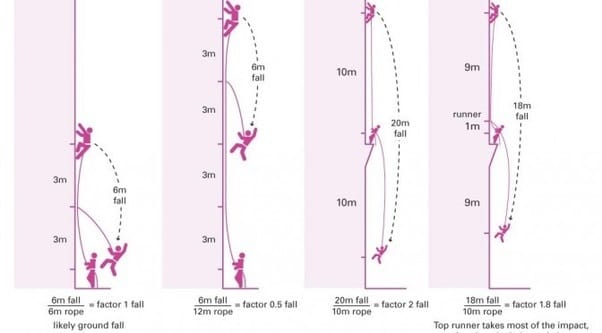

WHAT IS A FACTOR 2 FALL?

The fall factor is used to determine the severity of a fall while climbing. It ranges from 0 to 2, with Factor 2 being the most severe. The fall factor is the ratio between the height of the fall and the length of the rope. It will be Factor 2 when the height of the potential fall is twice the distance separating the climber from the anchor device.

Middle mark

Mark that indicates the halfway point of the rope. Increases safety and lets you know the point of the rope to be used for rappelling. Impact force. Impact or jerk experienced by the climber at the end of the fall. The lower this value, the lesser the impact of a fall will be. To certify the rope, the Impact Force is calculated for Factor 2 falls.

Number of Falls

According to the regulations, the rope must withstand a given number of falls at a determined frequency and impact force. This is calculated for Factor 2 falls. Ropes with the highest number of Factor 2 falls will be safer and stronger. If you exceed the number of falls, this does not necessarily mean that the rope will break, but rather that it will lose its shock absorption properties.

Static elongation

Elongation of a rope is calculated with an 80-kg weight hanging from it. Elongation cannot exceed 10% in single and twin ropes, and 12% in half ropes. The higher the elongation value, the lower the impact the climber will experience.

Sheath slippage

The rope has two parts: the sheath (woven exterior) and the core (strands in the inner part). Slippage is the movement inside the sheath under the conditions established in the standard. The less slippage, the better the performance of the rope.

Sheath percentage

Percentage of the mass of the sheath compared to the total mass of the rope. In other words, the higher the rope’s sheath percentage, the higher its resistance to abrasion. However, the core will be smaller, and so the number of falls will be lower.

Weight per metre

Kilograms per metre of rope. The lower the weight, the more manageable the rope will be. In contrast, heavier ropes tend to be more resistant.

-

Fixe Shark Dry Rope 9.8mm – 60m$329.00

Fixe Shark Dry Rope 9.8mm – 60m$329.00