Blog, Mountaineering

What Everyone Wants to Know About Snow Anchor Attachments

The Aspiring mid clip snow stake originated in the 1980s, following testing carried out in conjunction with the Federated Mountain Clubs. Aspiring snowstakes comply with the current recommendations for snow anchors developed by Don Bogie in collaboration with NZGA, NZMSC and LandSAR.

Introduction

While out on a recent skills course building snow anchors I began to think, which attachment really is the best and why? Is there data? After speaking with numerous people there are the solid ideas suggested by Bogie or the grey areas surrounding other methods in which the answer is usually “they are weaker but still strong enough”. But what is the strength difference?

This report is an expansion on Don Bogie’s testing carried out in 2005 and snow anchors in Grant Prattley’s Rope Rescue & Rigging Field Guide. These resources provide an understanding of how to construct a reliable snow anchor in various snow conditions. They suggest that the strength of snow anchors are dependent on a combination of the snow structure, anchor material, mode of use, angles and orientation, and placement of the attachment system. Bogie indicated further testing was required to assess “the best materials to use for snow anchors and their attachments”. This report aims to address this further testing required and assesses the strengths of materials and commonly used methods of attaching to a snow anchor.

How strong does an anchor have to be?

Bogie’s key points for snow anchor materials include only using attachments that have been tested and found to be greater than 10kN. This is due to any attachment point to a stake needing to be able to handle the anticipated load. Therefore any attachment material used needs to withstand 10kN independently. Furthermore, the UIAA 155 – International Climbing and Mountaineering Federation Safety Standard for Snow Pickets requires a snowstake to withstand a force of 8kN. It could therefore suggest that any attachment method used in conjunction with the snowstake needs to withstand forces above 8kN.

The sort of uses that snow anchors receive make it unlikely that one would receive the maximum sized loads. Snowstakes are mainly used for belaying on moderate angled slopes, belaying over crevasses, and abseil anchors. It would be highly unusual for a snow anchor to be used as the only anchor for a situation where a lead climber could take a fall factor 2 fall on steep terrain. The uses snow anchors are put to would give us the likely following loads for these situations:

- Leading on 45 degree slopes and belaying over crevasses – 4 kN to 8 kN

- Runners – 8 kN to 12 kN

- Top roping 1 person or abseiling – 2 kN to 3 kN

- Top roping 2 people- 3 kN to 4 kN

However, there are material strength issues with cables and stakes themselves which can make this hard to achieve. It would therefore seem that although there are some circumstances when snow anchors could receive over 10kN that this is unlikely for the type of use they normally receive so a target of 10kN for the strength of the components in a snow anchor would be a more realistic target to set.

To get maximum structural strength from a V section stake the point of the V needs to point towards the load when used as a top clip and the open part of the V needs to point to the load when used as a mid clip in weak to moderate strength snow. In very strong snow the orientation does not matter for mid clips as the snow provides the strength. This orientation would also apply to other types of open sections such as C-section.

There is a big difference in strength between the 6261 T6 alloy and the weaker alloys. Anyone using snow anchors made from the weaker alloys needs to be aware that their maximum strength could be well below the 10 kN target figure.

Report Objectives

- To assess the strongest method of attaching to a snowstake via a mid clip.

- To assess the strongest method of attaching to a snowstake via a top clip.

Commonly Used Attachment Methods

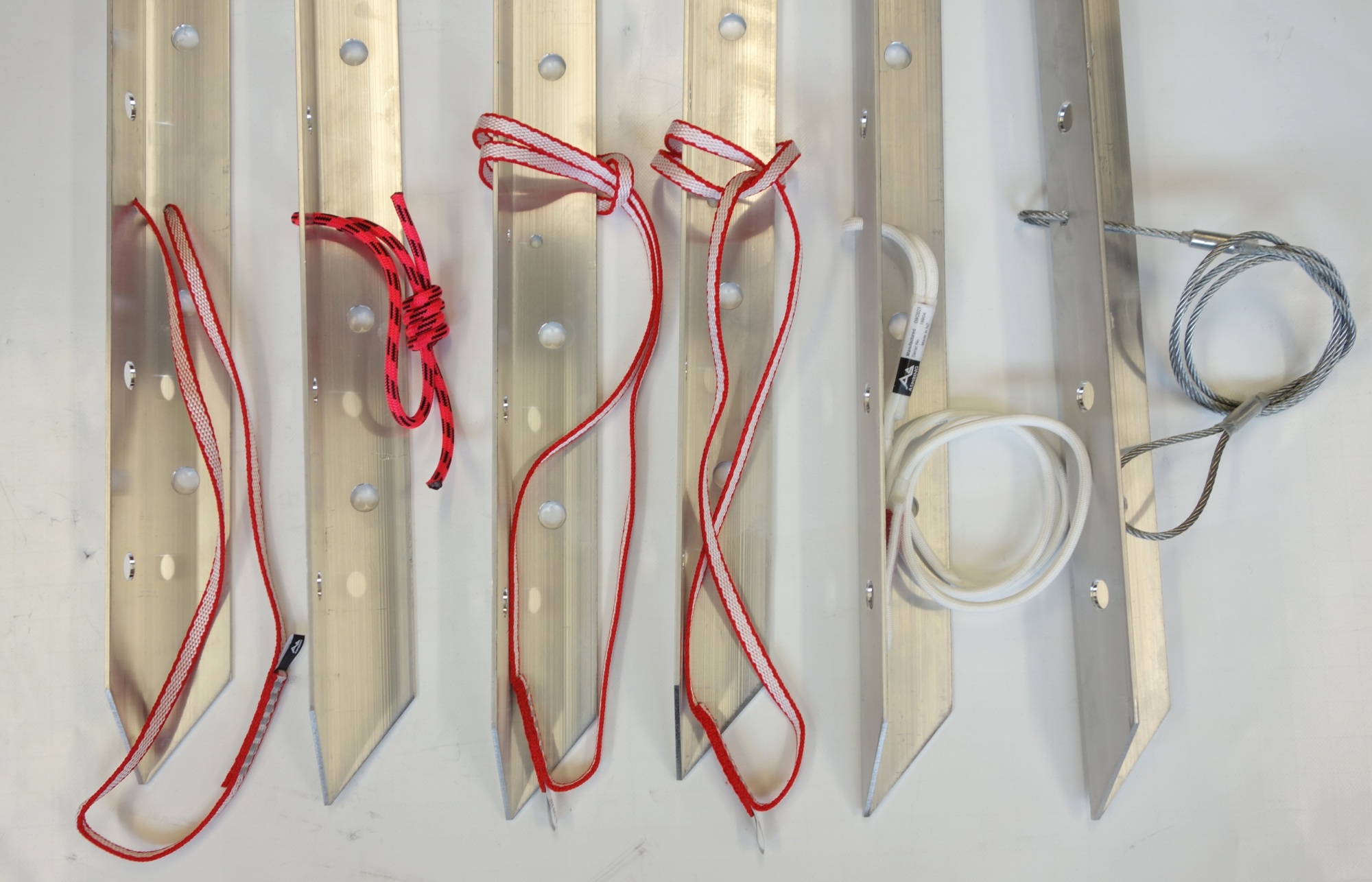

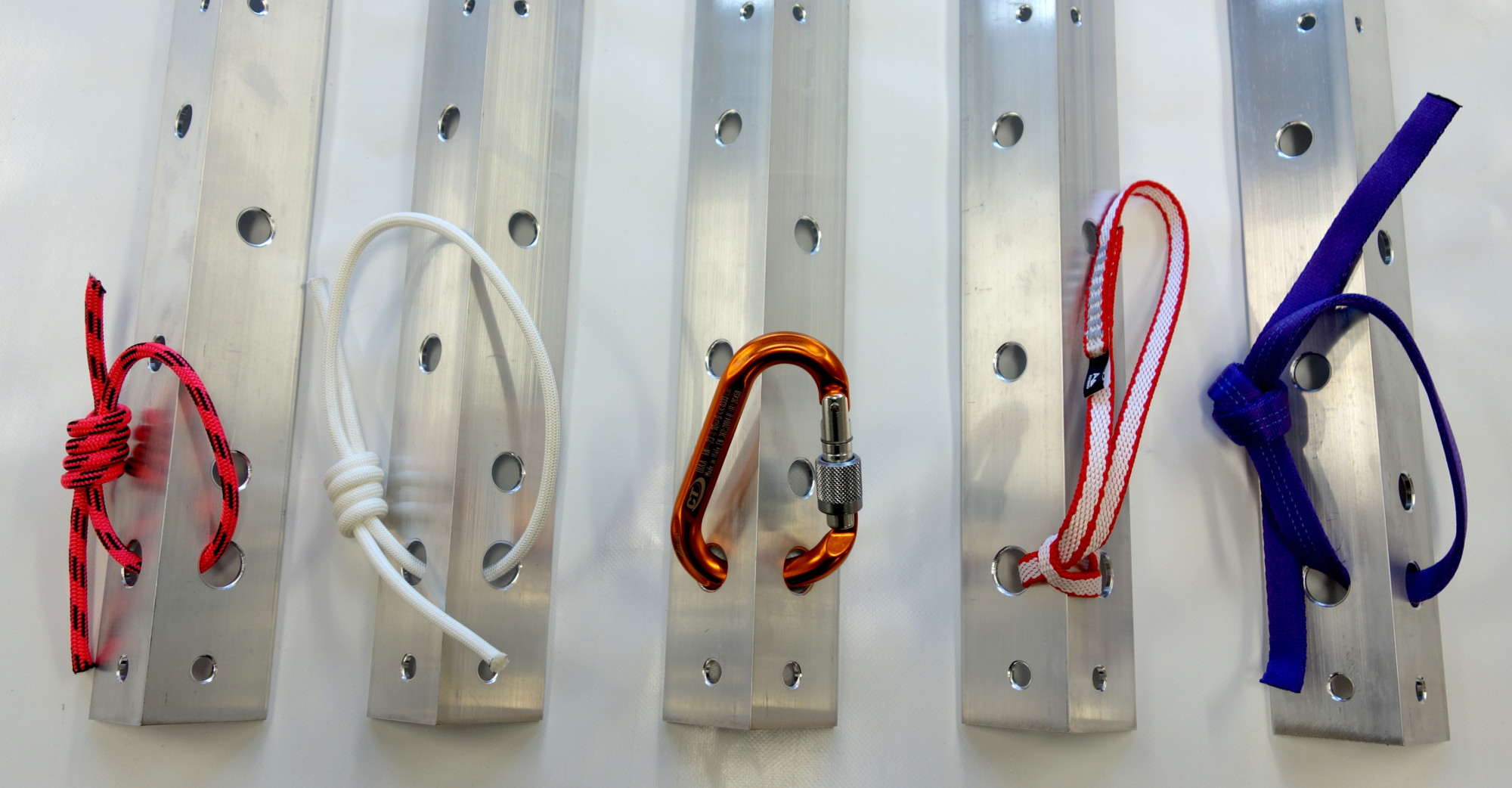

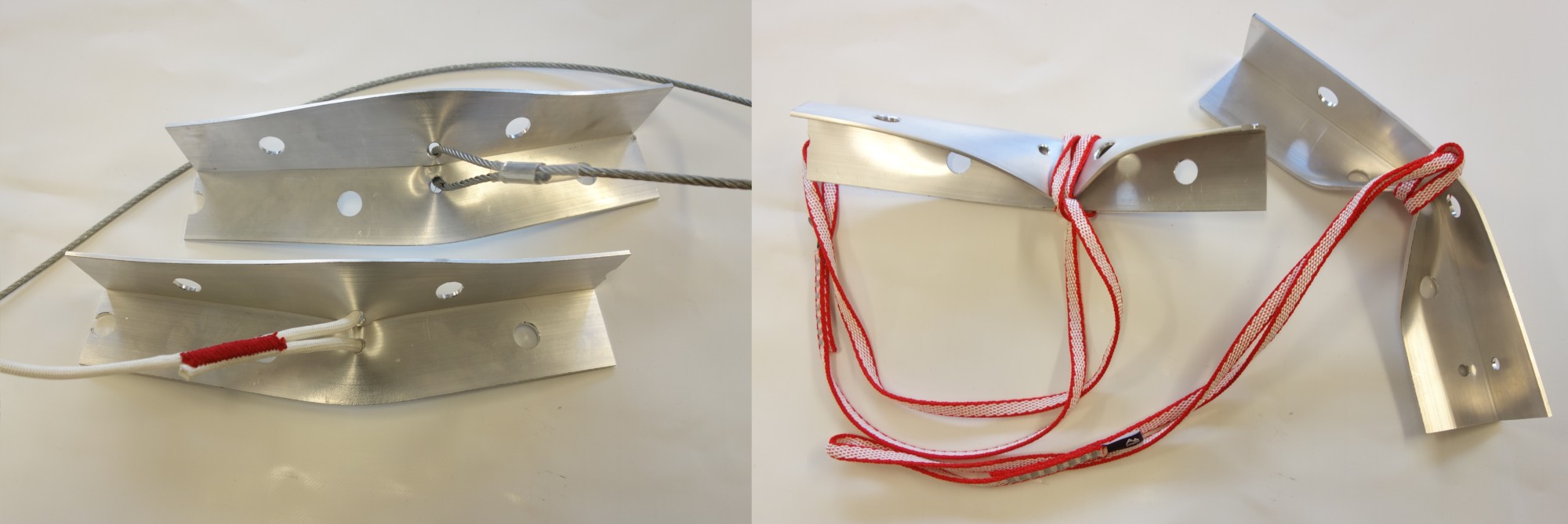

Mid Clip:

- 10mm Aspiring sling larks footed around snowstake.

- 10mm Aspiring sling clove hitched around snowstake.

- 10mm Aspiring dyneema webbing stitched loop through holes.

- 6mm Fixe accessory cord loop through holes finished with a double fisherman’s.

- 4mm Aspiring galvanised steel cable with attachment eye die-pressed swages through holes.

- 5mm Aspiring dyneema cord stitched single strand with sewn eyes through holes.

Top Clip

- 10mm Aspiring sling larks footed through holes.

- 16mm Aspiring nylon tape loop through holes finished with a tape knot.

- 6mm Fixe accessory cord loop through holes finished with a double fisherman’s knot.

- 5mm Aspiring dyneema cord through holes finished with a double fisherman’s knot.

- Climbing Technology Snappy HMS carabiner through holes.

Testing Materials

6261 T6 alloy Aspiring Safety Snowstake:

- Point of the V to load is down hill for top clip attachment.

- Open part of the V to load for mid clip attachment.

Attachment Methods:

- 10mm Aspiring Sling – 22kn

- 6mm Fixe Accessory Cord – loop with double fisherman’s – 11kn

- 4mm Galvanised Steel Cable – 16kn

- Aspiring 5mm Dyneema Cord – Eyed stitched single strand – 12kn

- Climbing technology Snappy HMS Carabiner – 22kn

- 16mm Aspiring Nylon Loop with tape knot – 12kn

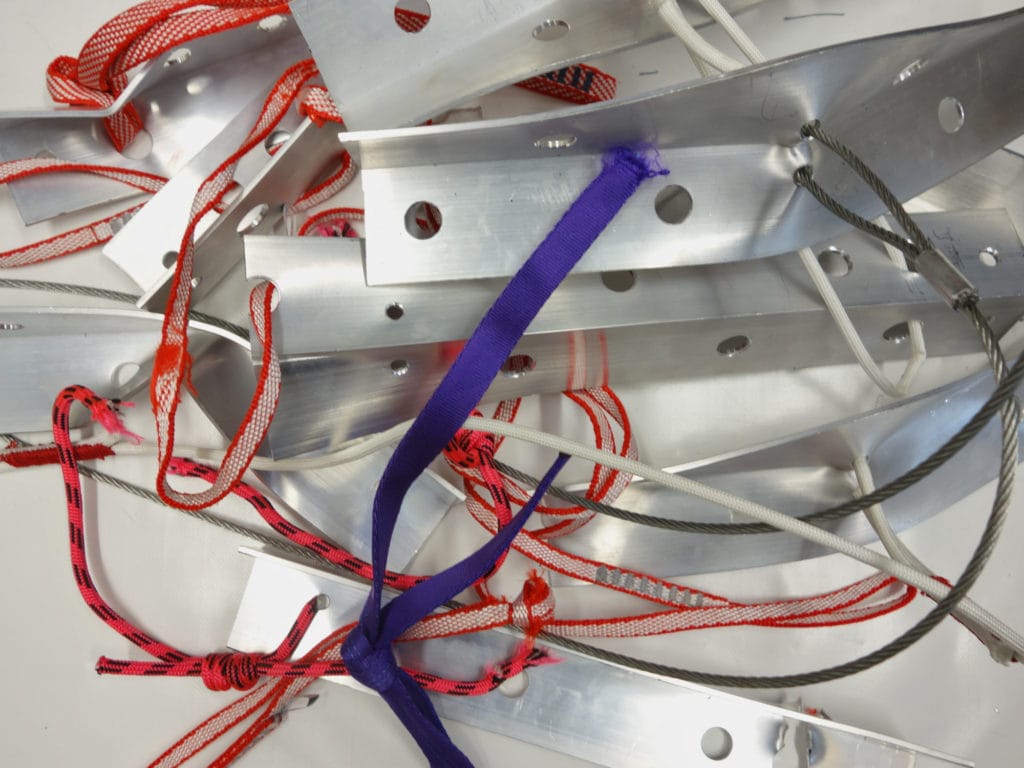

Methods

General Set-up Methods

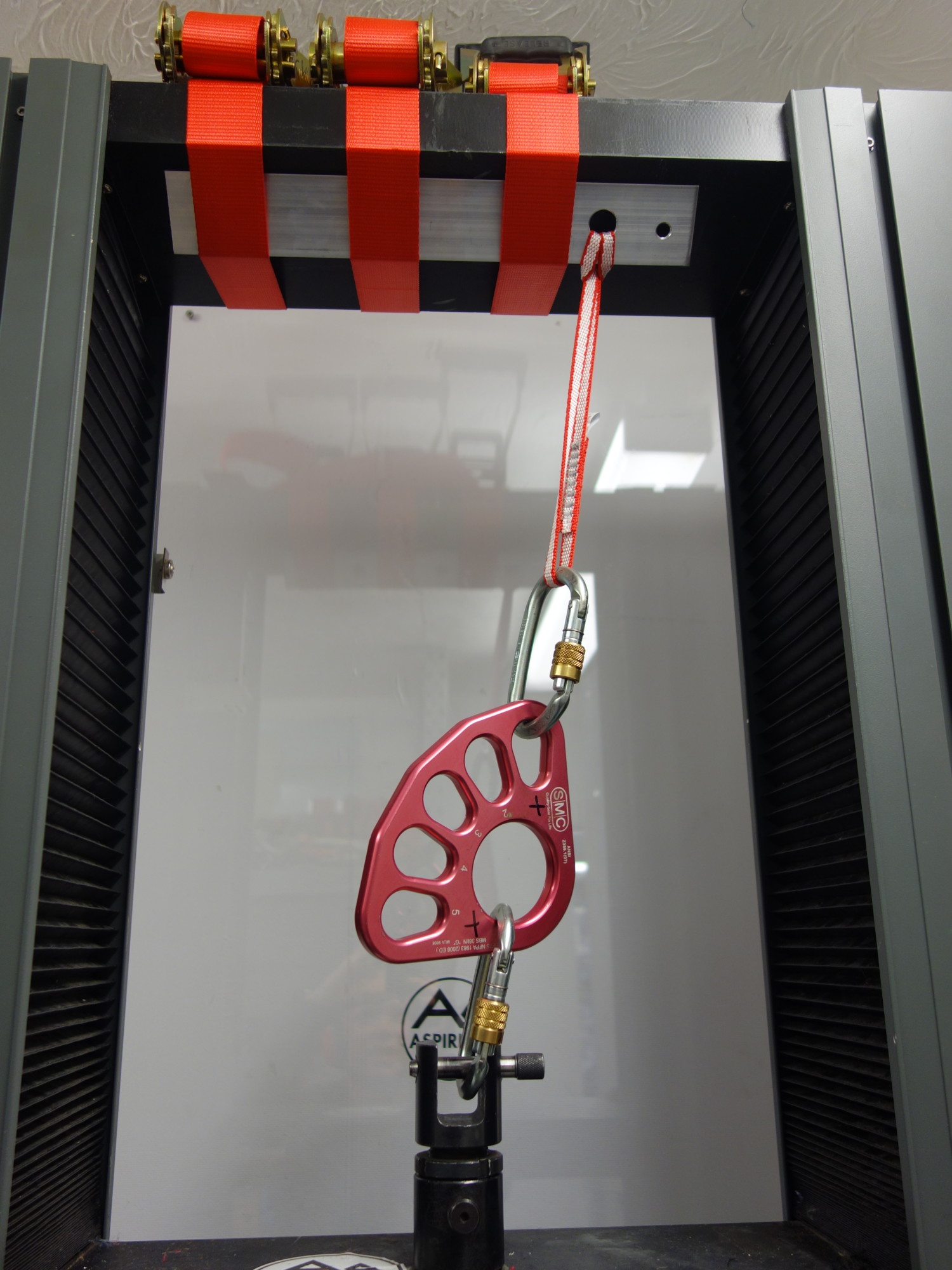

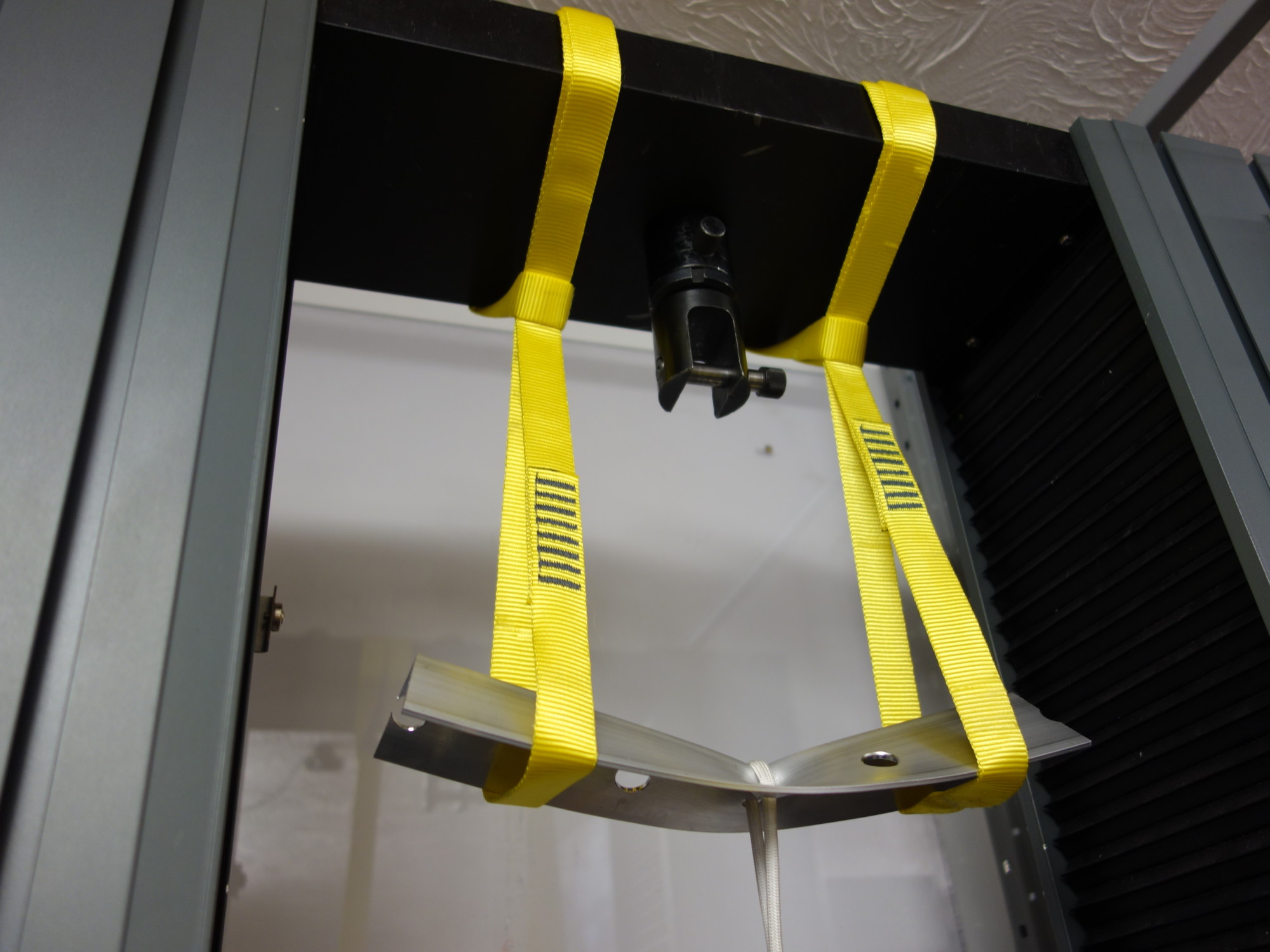

Set-up is undertaken as per the UIAA 155 Snow-picket testing which is the test method for snow pickets for use in mountaineering. In this UIAA standard each hole needs to withstand a force of 8kn. This standard is used as the recommendation for the set-up to test the different attachment methods.

The top-clip attachment of the snowstake is supported on the testing machine with three ratchet retaining slings on the left side of the snowstake attachment with the point of the V to the load. The attachment is placed through the two top holes. The attachment is then clipped into an additional carabiner and attached to a rigging plate. This rigging plate enables the force to be pulled in a straighter line. The snowstake for the top clip attachment has been reduced in length by 25cm to enable the snowstake to fit into the machine. Ratchets ensure that the snowstake does not release during testing and the pull is on the top holes. As the purpose of this test is to asses the strength of the top holes this is seen as the most practicable way to achieve in this testing environment.

The mid-clip attachment snowstake is supported on the testing machine with two retaining slings, 4cm on either side of the snowstake with the open part of the V to the load. The attachment is placed over the mid-clip or through the mid-clip holes. The snowstake has been reduced in length by 10cm on either side to enable the snowstake to fit into the testing machine.

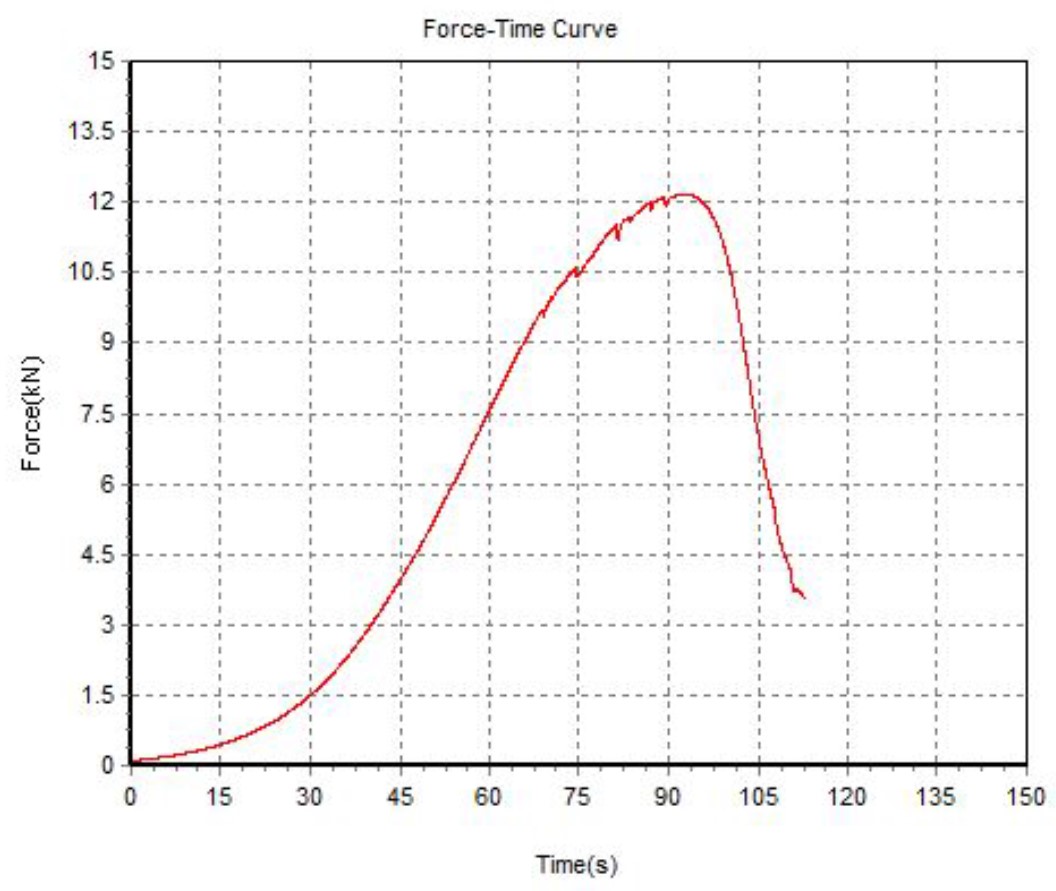

Slow pull Tests

Each testing series recorded the slow pull test set up.

The slow pull testing was in one location.

- Aspiring Safety, 1/6 Burdale Street, Riccarton, Christchurch, New Zealand. https://www.aspiring.co.nz/

- Vertical testbed 1.6m

- Maximum Test Force 100kN, sample rate 60 per second

- Testing speed 80mm per/minute

- Testing was stopped if the snowstake was going to pull out from the retaining slings.

- Two of each test were undertaken.

Findings

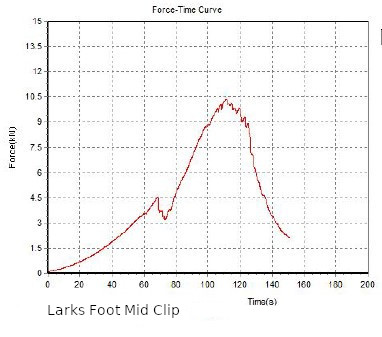

Mid Clip

| Test | kN | Comment |

| Larks foot around snowstake using Aspiring 10mm sling |

4.6kN Peak Load 5.491kN |

4.6kN the angle of pull shifted towards the synced end. Stake proceeded to deform. Compacted at the centre. |

| Clove hitch around snowstake using Aspiring 10mm sling |

7.05kN Peak Load 8.70kN |

Snowstake started deforming at 7.05kN with wear on the sling from edges of snowstake, snowstake compacted at the centre. |

| 10mm Aspiring dyneema webbing stitched loop through holes |

8.65kN Peak Load 14.67kN |

Deformation to snowstake at 8.65kN. Broke hole on snowstake at 14.022kN with severe abrasion to the webbing. Both holes broke at 14.67kN. No stopping of test required due to broken holes. |

| 6mm Fixe accessory cord loop through holes finished with a Double Fisherman’s |

5.7kN Peak Load 8.19kN |

Cord broke on hole at 8.19kN, snowstake deformation outwards from the centre at 5.7kN. No stopping of test required as cord broke. |

| 4mm Aspiring galvanised steel cable with attachment eye die-pressed swages through holes |

13.52kN 13.52kN Peak Load |

Deformation of Snowstake at 13.52kN, deformation outwards from the centre. No wear to cable. |

| Stitched single strand with sewn eyes through holes using Aspiring 5mm dyneema Cord |

9.653kN Peak Load 12.17kN |

At 9.653kN the snowstake started deforming. No abrasion to the cord, deformation outwards from the centre. |

Top Clip

| Test | kN | Comment |

| Aspiring 10mm sling Lark’s Footed through holes | 9.87kN | Snowstake twisted and the sling broke through one hole and then through the other. |

| 16mm Aspiring Nylon Tape through holes finished with a tape knot | 8.97kN | Tape broke on the snowstake holes. |

| 6mm Fixe Accessory Cord Loop through holes finished with a Double Fisherman’s | 8.97kN | Cord broke on the snowstake holes. |

| Climbing Technology HMS Carabiner through holes at the top | 15.30kN | Test could not show maximum force that could be exerted on the snowstake as the ratchet broke and the test was stopped. |

| Aspiring 5mm Dyneema Cord | 13.42kN | Test could not show maximum force that could be exerted, the snowstake was pulled through the ratchet straps and the test was stopped. |

Conclusion

Mid-clip attachment

- The permanent mid clip attachment through holes needs to withstand a force of more than 8kn and be unsusceptible to abrasion.

- There is significant strength differences when placing the material through the mid clip holes and around the snowstake.

- Mid clip attachment through the holes created an outward deformation of the stake compared with the stake collapsing and bending in on itself when the attachment is placed around the snowstake.

- 10mm Aspiring dyneema webbing stitched loop through holes created the highest possible testing force however severe abrasion occurred and deformation to the snowstake occurred lower than other methods. Therefore, this is not a permanent solution.

- Aspiring 4mm galvanised steel cable through holes was the strongest method of attachment and withstood forces over 8kN and no abrasion occurred.

- Stitched Aspiring 5mm dyneema cord withstood forces over 8kN before the stake started deforming and no abrasion occurred. This material stitched on it’s own is rated to 12kN where it breaks in the core.

- When attaching a sling around the centre of the snow-stake the clove hitch performed higher than the larks foot. The Larks foot displaced at a lower kN rating which suggests that this could cause anchor failure.

Top-clip attachment

- All attachment methods withstood 8kN.

- Carabiner attachment and dyneema cord performed over 10kN force.

- Larks footing a sling through the top attachment created twisting to the Snowstake.

- Using a carabiner creates the highest force pull.

- Using dyneema cord created the next highest force, however the tails on dyneema cord need to be kept long to allow for the cord to slide when tightening at higher forces.

- Using loops through the top holes creates a straight pull and no affect to the V shape.

- Larks footing was the only method that created the stake holes to brake.

Recommendations

- In general having tape or cord go over sharp metal edges is not recommended due to the possibility of the material being cut.

- When stakes are used as top clips, clipping a karabiner directly into the stake provides the most secure attachment point and created the least deformity.

- If not using a karabiner as the top clip using Aspiring dyneema cord loop finished with a double fisherman’s allowed for the next greatest force to be exerted.

- Avoid using a lark’s footed sling as it creates a twisting movement and displacement of the snowstake.

- When building snow anchors with a mid clip using a 4mm galvanised steel cable is recommended for rescue use.

- The next strongest alternative is using the 5mm Aspiring Dyneema cord.

- When using something as a permanent attachment system the material needs to avoid any abrasion.

This report has led to us creating a new option for our snowstakes. They are now available with stitched dyneema through the middle holes.

Is there is a method you use that we didn’t review? Get in touch and we will do some further testing!

Writing and testing by Natasha Mealing

References

Bogie, D. (2005) Snow Anchors. New Zealand, Viewed 28 July 2021, https://www.aspiring.co.nz/wp-content/uploads/2016/05/Snow-Anchors0705.pdf

Braun-Elwert, G. (2005) Belays on snow, New Zealand, Viewed 28 July 2021, https://www.alpinerecreation.com/pdf/safetyresearch_snowbelays2005.pdf

Bogie, D. (2010) Snow Anchors for Belaying and Rescue, Viewed 28 July 2021, https://arc.lib.montana.edu/snow-science/objects/ISSW_O-061.pdf

Prattley, G. (2020) Rope Rescue and Rigging: Field Guide, 3rd Edition, Stone Paper, New Zealand