Fall protection equipment requires careful maintenance. A record must be kept for each item showing its date of purchase and recording periodic inspections carried out at a specified interval. Typically, this could be done every six months. Ropes, harnesses, and lanyards should be stored away from sunlight in a cool place. Metallic items should be stored in a dry place. All equipment should be kept as clean as possible.

A retirement guide-line must be available so that any deterioration or excessive use of the equipment can be compared with the guideline, and if permitted deterioration or usage levels are exceeded, the item must be retired, usually by destroying it. This link will take you to the website page on Equipment Inspection.

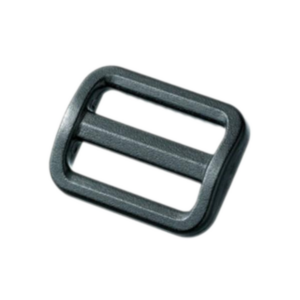

Harnesses and other webbing equipment should be checked for wear and damage to the webbing and stitching, distortion and corrosion of hardware, and correct function of buckles. Webbing equipment should not used for more than ten years, even if it is apparently in good condition.

Ropes should be checked for cuts and abrasion damage. The rope should have a uniform feel along its length. Ropes also should be retired after a maximum of ten years.

Karabiners, snap-hooks, and screw-links should be checked for correct function of the closure. If sprung latches are not closing properly, they should be cleaned and lubricated carefully, and retired if the problem cannot be resolved. Triple-lock karabiners are particularly prone to closure failure.

Self-retracting life-lines should be inspected according to the manufacturer’s instructions, and returned to the supplier if maintenance is required.